Refrigerated Transport

Refrigerated transport plays a crucial role in the carriage of goods that require strictly defined conditions. We provide these services on both domestic and international routes. We organize such transports from start to finish—planning the route, selecting the appropriate vehicle, and managing the temperature. Thanks to our experience and specialized logistics expertise, the Woz-Trans team successfully executes even the most demanding orders.

What is refrigerated transport?

Refrigerated transport involves carrying goods at a constant, controlled temperature. We maintain these conditions from the moment of loading until unloading. This is absolutely essential for products sensitive to temperature fluctuations. Most commonly, these include fresh meat, fish, dairy products, fruits, and vegetables. We also transport medicines, chemical products, and cosmetics under temperature-controlled supervision.

We offer Full Truckload (FTL) and Less-than-Truckload (LTL) services. We always adjust the temperature in the semi-trailer to the type of cargo being transported, ensuring its safety and quality.

The refrigerated transport market and trends in Poland

The refrigerated transport market in Poland is growing at a rapid pace. An increasing number of customers expect fresh, high-quality products to be readily available. The rise in sales of portioned meat, fresh fish, and dairy products necessitates regular, smaller deliveries.

For food with a very short shelf life, we use special transport systems and maintain temperatures between 0°C and +2°C. Night and weekend deliveries, as well as seamless client communication, are becoming increasingly important.

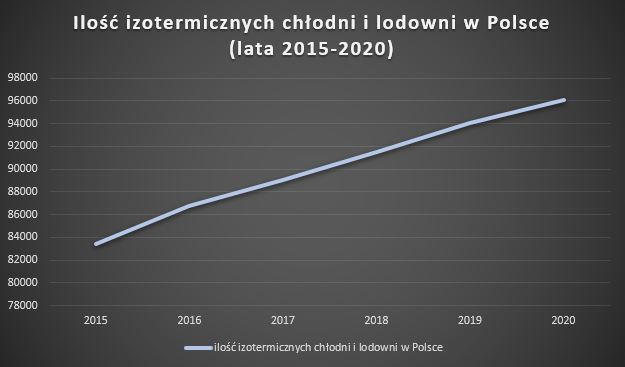

According to data from Statistics Poland (GUS), the number of refrigerated vehicles in Poland is constantly increasing. In 2015, there were over 83,000. By 2019, this number had risen to over 94,000. Data for 2020 indicates over 96,000 refrigerated and freezer vehicles.

Although GUS has not provided more recent data, it is estimated that this number now exceeds 100,000. Organizing this type of transport is significantly more demanding than standard transport.

Types and applications of refrigerated transport

Refrigerated transport serves many industries, from food to pharmaceuticals. In the food sector, we transport fresh meat, fish, vegetables, fruits, and deep-frozen products like ice cream. A specific transport temperature applies to each commodity, in accordance with the international ATP Agreement, which Poland joined in 1984. We transport poultry at a maximum of +4°C, butter at +6°C, and fish on ice at +2°C.

The pharmaceutical industry uses refrigerated transport for medicines and vaccines, where the slightest temperature deviation can destroy the product. Our services are also used by companies in the cosmetic, chemical, and floristry sectors.

What goods are transported under controlled temperature?

Perishable food is the most common cargo transported in refrigerated vehicles. Meat (fresh and frozen), fruits, vegetables, and ice cream must reach their destination quickly—usually within 48 hours. The products require appropriate cooling, freezing, or sometimes heating. For international transport, the primary legal framework governing the carriage of foodstuffs is the ATP Agreement.

An interesting case is the transport of liquid chocolate—we maintain a temperature of around 40°C in food-grade tankers. Too low a temperature causes the product to solidify, leading to immense difficulties during unloading.

Goods requiring controlled temperature include, among others:

- food of animal and plant origin,

- confectionery products,

- pharmaceutical intermediates,

- meat and cured meats,

- agricultural products,

- plants and mushrooms,

- cosmetics,

- ADR cargo,

- cut flowers,

- medicines,

- beverages.

In addition to temperature, we also control air humidity and avoid transporting products that may react with each other.

Cryogenic transport

Cryogenic transport is the carriage of goods in dry, bacteriostatic ice. It is used by medical and pharmaceutical facilities, universities, and hospitals. We perform such transports for hospitals, laboratories, universities, and pharmaceutical companies. In this way, we transport:

- blood,

- biological material,

- medical equipment,

- surgical tools,

- organs,

- medicines.

What vehicles can be used for refrigerated transport?

As previously mentioned, organizing refrigerated transport also requires selecting the appropriate type of semi-trailer. Woz-Trans freight forwarders will assist in choosing the right means of transport for goods requiring controlled temperatures. Currently, temperature-controlled transport is most often carried out using the following types of vehicles:

- Refrigerated trailer (Reefer) – equipped with a refrigeration unit, ideal for long distances. They can be divided into three types:

- Double-deck (Doppelstock) – with a dual-level loading system, thanks to a movable floor;

- Multi-temperature trailer – with a partition wall, allowing for different temperature zones,

- Trailer with a hook system – e.g., for pork carcasses.

- Insulated vehicle – with an insulated body, used for shorter routes;

- Ice-cooled vehicle – cooled with dry ice.

- Heated transport units – e.g., food-grade tankers for liquid chocolate. We most commonly maintain temperatures from +25°C to -25°C.

Typically, refrigerated vehicles transport goods in temperatures ranging from +25°C to -25°C, although there are exceptions, such as the previously mentioned transport of liquid chocolate.

How does refrigerated transport work?

Refrigerated transport is a multi-stage logistics process. First, we analyze the client’s needs and select the appropriate vehicle. Before loading, the semi-trailer is washed, disinfected, and pre-cooled. The cargo is positioned to allow for free air circulation.

During transit, we constantly monitor the vehicle’s temperature and location. We archive the data as proof of maintaining the cold chain. Safety in refrigerated transport is ensured by certified temperature recorders and modern telematics systems with GPS. These allow the freight forwarder to have real-time access to information about the cargo’s location and temperature.

During transit, we constantly monitor temperature and location, recording the data in our system. Thanks to telematics and GPS, we can react immediately to any deviations, minimizing the risk of loss.

Documents, standards, and certificates in refrigerated transport

ATP Certificate

Every vehicle must have an ATP certificate. It undergoes a simplified inspection every 3 years and a full inspection every 6 years. Additionally, we apply the HACCP system, the ISO 22000:2005 standard, and Good Distribution Practice (GDP) principles for pharmaceutical transport. If required, we can provide veterinary or phytosanitary certificates.

Requirements for refrigerated transport drivers

Drivers operating refrigerated vehicles must meet additional requirements. Primarily, the driver should have undergone medical and laboratory examinations at a sanctioned public health authority. Furthermore, they must possess a valid medical certificate confirming there are no contraindications to performing work associated with the risk of infecting others.

Risks and prevention methods

The greatest risks associated with refrigerated transport are temperature fluctuations and delivery delays. To counteract them, Woz-Trans employs continuous online temperature monitoring and advanced IT tools (ETA), which allow for a reaction to potential threats and prevent a loss of quality in the transported goods.

Drivers of refrigerated vehicles are often exempt from traffic restrictions on holidays or weekends, which shortens delivery times.

Most companies specializing in refrigerated transport offer additional insurance packages to protect goods throughout the entire journey. For refrigerated transport to be successful, suitably adapted vehicles and a well-thought-out logistics process are essential. Such operations are carried out only by professional transport companies that, thanks to their knowledge and experience, attend to every detail of the transport.

Entrust your refrigerated transport to professionals

The carrier is responsible for delivering the shipment in perfect condition. This is particularly crucial in refrigerated transport, as the goods require maintenance of a precisely defined temperature.

Most food products have short shelf lives, making the shortest possible delivery time essential. Drivers of refrigerated vehicles are subject to the same driving time regulations as in other types of transport. For this reason, any delay can generate significant costs associated with maintaining the required transport conditions. Therefore, the route planning stage is key. It requires a thorough analysis of the route for potential difficulties.

Refrigerated transport carries certain risks, yet the demand for such services is constantly growing. This is particularly evident in the dynamically developing food sector. A further increase in the number of refrigerated vehicles is expected, along with the introduction of new technologies that will further streamline this process.

Organization of refrigerated transport – Woz-Trans

Refrigerated transport requires the carrier to provide proof of temperature maintenance throughout the entire route. Clients often require printouts from temperature recorders (thermographs), which are a key document in the event of potential claims or damage to the transported goods.

Important: In refrigerated transport, the printout from the temperature recorder (thermograph) is as crucial as the transport documents (CMR or Waybill). In the event of damage to the goods, e.g., melted ice cream, this printout will be the most important piece of evidence regarding the carrier’s fault or lack thereof. It will indicate the temperature that was maintained both during transit and during stops.

We hope to have convincingly demonstrated our competence in organizing all types of refrigerated transport. Executing refrigerated transport requires a well-thought-out logistics process, professional route planning, and an experienced team of freight forwarders and drivers, which we have at our disposal. This gives our clients the guarantee that their products will arrive at their destination in pristine condition, in accordance with all requirements and standards of refrigerated transport.